AURELI MARIO è dal 1968 azienda leader nella coltivazione e trasformazionedi ortaggi in ingredienti naturali per il settore Alimentare

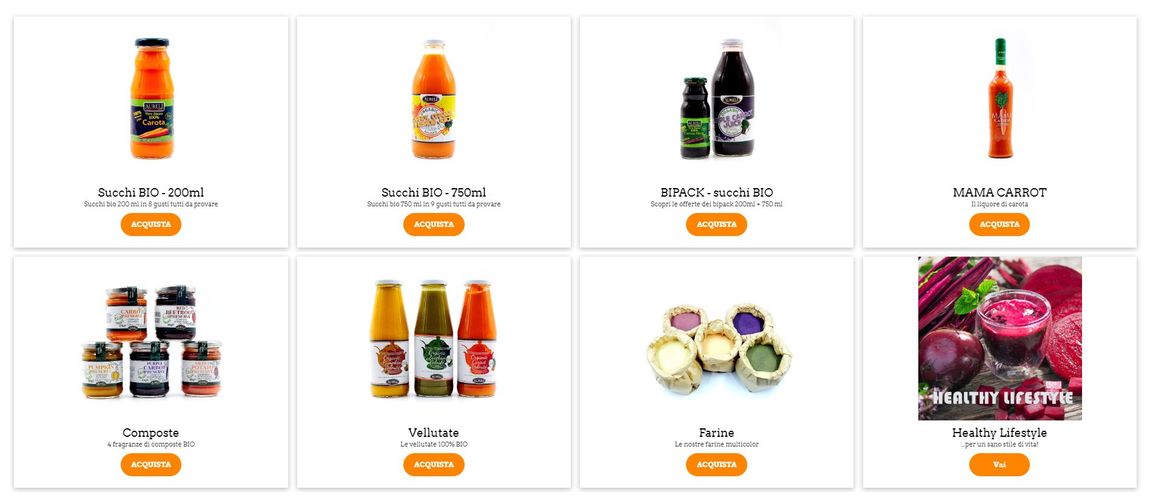

I nostri SETTORI

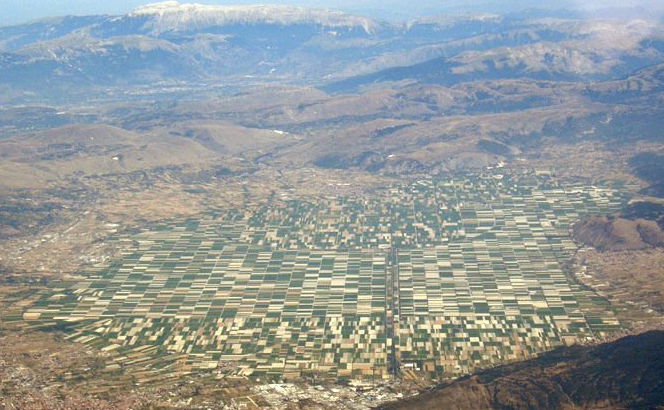

ABRUZZO - La regione dei Parchi e Cuore Verde D'ItaliaL'idea imprenditoriale nasce dal territorio e dalla sua secolare vocazioneper un'agricoltura

praticata nel rispetto dell'ambiente in cui opera.

Qui, nell'Altopiano del Fucino, Aureli valorizza la propria Terra e lepersone per creare un legame unico con la natura che si trasmettedal campo alla tavola.

Food Solution

LE NOSTRE IDEEper l'industria alimentare

Applicazioni

-

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante -

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante -

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsanteTitolo diapositiva

Scrivi qui la tua didascaliaPulsanteTitolo diapositiva

Scrivi qui la tua didascaliaPulsante

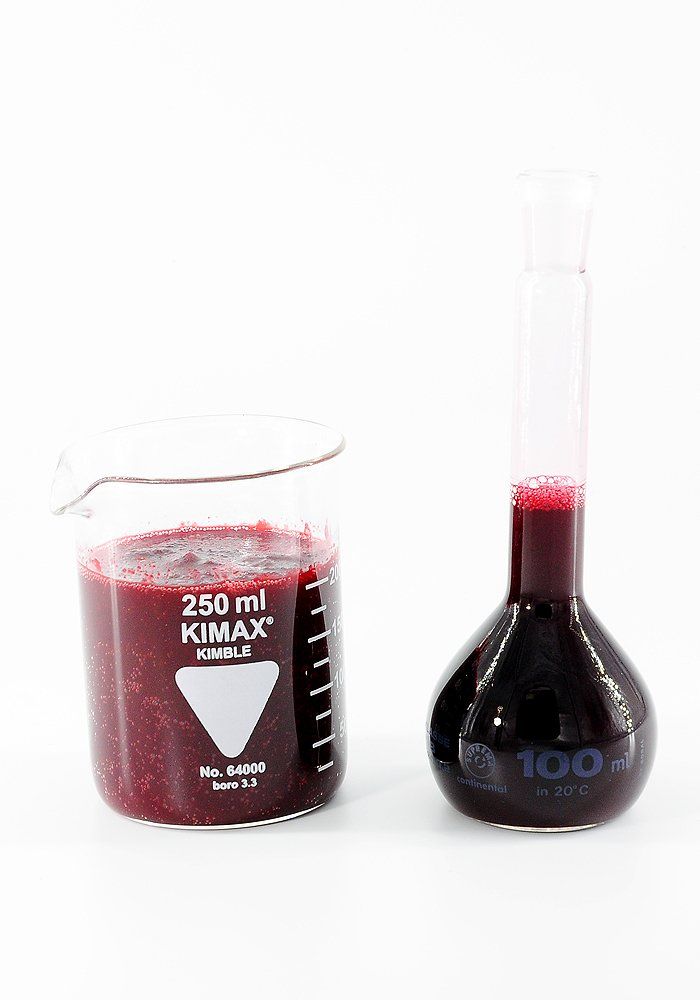

Reparto Ricerca e Sviluppo (R&D)

Il reparto di Ricerca e Sviluppo è costituito da 15 unità di personale composto da laureati in Scienze Biologiche, Ingegneria Meccanica, Tecnologie Alimentari, Chimica Analitica, Agronomia ed è diretta da Walter Aureli. L’attività di ricerca industriale e sperimentale si svolge lungo tutta la filiera di produzione: dal campo alla raccolta, impacchettamento e conservazione; dallo sviluppo di nuove pratiche agronomiche ed individuazione di nuove matrici biologiche per il miglioramento della resistenza delle piante all’aggressione da patogeni ed infestanti, al miglioramento della qualità; dallo sviluppo di nuove tecnologie per l’ottimizzazione dei processi di trasformazione delle materie prime per la produzione di succhi, purea, essiccati e sfarinati per uso alimentare, alla valorizzazione dei sottoprodotti di lavorazione; dalla ideazione di nuovi prodotti per una alimentazione indirizzata alle richieste nutrizionali più specifiche per bambini, persone anziane e sportivi, all’applicazione di tecnologie analitiche per la definizione completa dei nutrienti dei prodotti freschi e trasformati. In questo contesto una particolare attenzione del reparto R&D è nell’attività di economia circolare per il riutilizzo dei sottoprodotti di lavorazione per la produzione di energia elettrica e termica tramite la produzione biotecnologica di biogas, con l’obiettivo di raggiungere il massimo sostentamento energetico dell’azienda con una minore produzione di CO2, in linea con le raccomandazioni della comunità europea. R&D della Azienda Aureli si avvale della collaborazione di diverse Università Italiane. Dal 2013 ha accordi di collaborazione di ricerca con il Dipartimento di Biologia Ambientale, Dipartimento di Chimica e il Dipartimento di Biologia e Biotecnologie C. Darwin dell’Università degli Studi di Roma “La Sapienza”.

NEWS: Alimenti specifici per combattere la

sindrome LONG COVID

Succo di Barbabietola Rossa

Modifica disciplinare di produzione - Carota dell'Altopiano del Fucino IGP

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

AURELI#multimedia

La raccolta delle CAROTE - CARROT Harvest

AURELI#multimedia

La raccolta del MAIS

- CORN Harvest

Customer CARE

Il nostro TEAM a Vostra disposizione

Contatti

Grazie per averci contattato.

Ti risponderemo il prima possibile

Spiacenti, si è verificato un errore durante l'invio del messaggio.

Per favore riprova più tardi

Interessati ai nostri prodotti?Siamo qui per aiutarvi!

CREDITS

Il laboratorio Qualità è composto da sette unità operative che si occupano delle analisi chimiche, microbiologiche e fisiche della materia prima in ingresso, del prodotto fresco e del trasformato.