QUALITY, A KEY FACTOR

We are committed everyday to achieve a superior Quality during all our production chain.

01

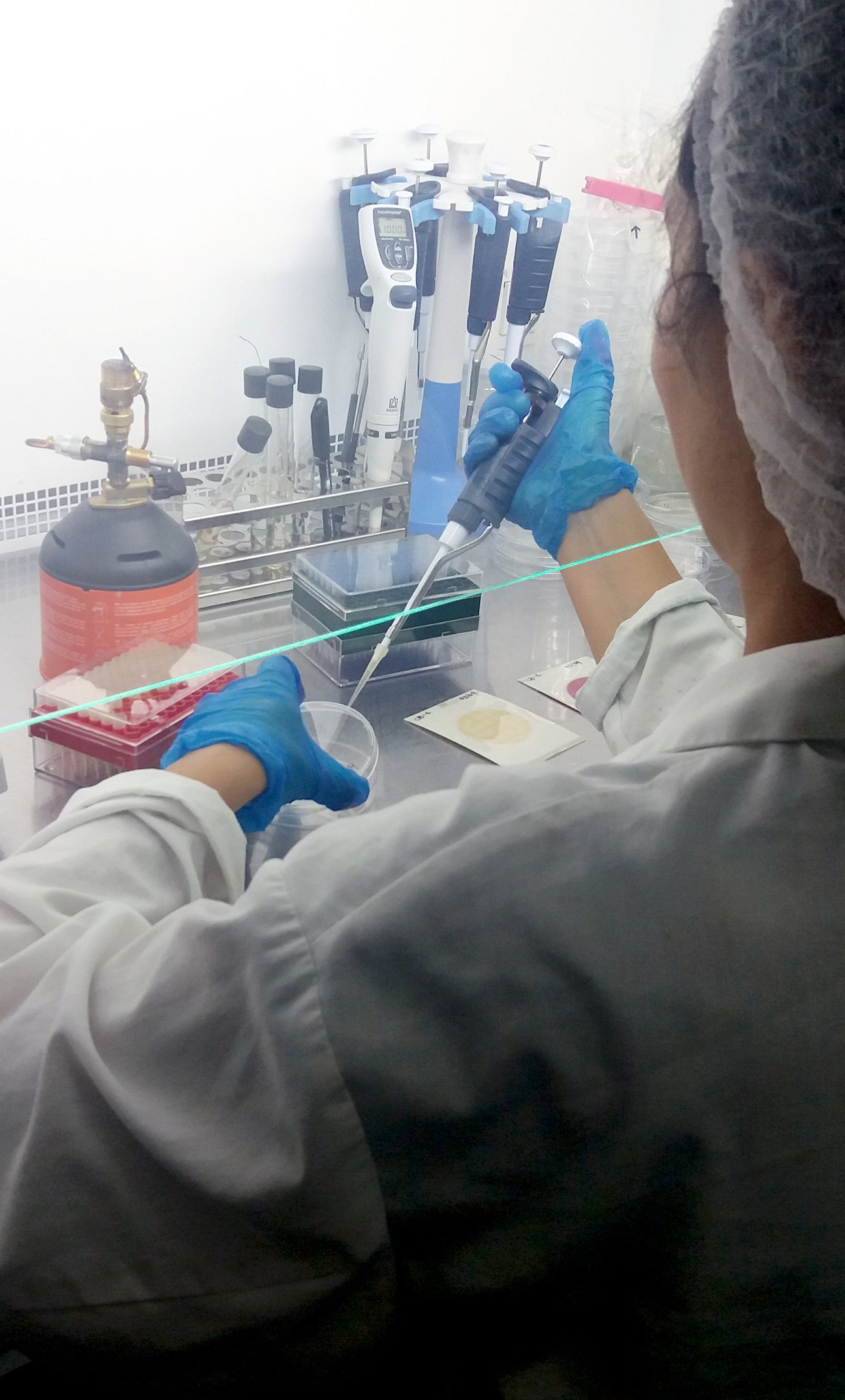

Our Quality Control System

Our Quality Control System

The Quality Control is a key factor involved during the whole production process from the cultivation to the transformation. Our Quality Department manages internal labs for online production analyses, as well as external laboratories ISO certified and approved by ACCREDIA.

According to Aureli, Quality is:

- The Quality of the Product

- The Quality of the Process

- Quality for the Environment

The big efforts made by Aureli to reach the highest quality standards for product and manufacturing is proven by several quality certifications and accreditations:

Further guarantees to its customers are the periodic Audits carried out by IFS competent inspectors and by Organic Authority which systematically verify the conformity of the production process, the safety of products obtained and the compliance with the specifications of the Organic Agriculture Regulation.

02

Quality of the Product

Production batch setting and controls on the field.

Analyses and controls start from the cultivation process with sampling made for each production batch representative of a single plot and during the growth phase and the harvest phase of the crop.Analytical controls are aimed to define the level of possible chemical pesticides residues of the cultivation, than chemical-physical components of the product are analysed.

Analysis are than focused on organoleptic characteristics such as taste, smell and colour; special attention is for the microbiological values of the product.

Samples are picked up at the beginning, during and at the end of the production process.

Aureli internal labs draw up a technical sheet for each production batch containing all detailed values.

Special attention is paid to product traceability analysis made at the picking up of the raw material before starting the transformation process.

Production batch setting and controls on the field.

Analyses and controls start from the cultivation process with sampling made for each production batch representative of a single plot and during the growth phase and the harvest phase of the crop.

Analytical controls are aimed to define the level of possible chemical pesticides residues of the cultivation, than chemical-physical components of the product are analysed.

Analysis are than focused on organoleptic characteristics such as taste, smell and colour; special attention is for the microbiological values of the product.

Samples are picked up at the beginning, during and at the end of the production process.

Aureli internal labs draw up a technical sheet for each production batch containing all detailed values.

Special attention is paid to product traceability analysis made at the picking up of the raw material before starting the transformation process.

03

The Quality of the Process

The Quality of the Production Process is focuses on production plant parameters and on the conditions of the production area.

Start of ProcessThe analysis are aimed to verify that the raw materials introduced in the process comply with the specifications of the finished product according to the customer’s needs.

Production in progress

The analysis verify the compliance of the production process or the possible need to carry out sudden changes to be made to obtain requested quality parameters.

End of the Process

Once manufactured and aseptically packed, the product is quarantined for further "microbiological" checks. The analysis are aimed to detect: total bacterial count (TBC), yeasts and molds, lactobacilli, total coliforms.

Production Facilities

For the various types of production machines, especially for agro-industrial processes, are systematically detected:

-plant data: temperature and pressure;

-process water: verification of drinking degree of water used in washing and production process

-production premises: in the various production plants the degree of hygiene is checked using pads, or immediate pads (bioluminometer)

04

The Quality of the Environment

Respect for the Environment and integration into the Territory to which AURELI belongs, have always been two milestones of AURELI's philosophy.

The company is located at the border of the "National Park of Abruzzo, Lazio and Molise" and is well integrated with this Environment, whose naturalistic drive has always inspired and characterized all company production process.

In order to assess and control the environmental impact, AURELI has created a very modern biological Purifier Plant to monitor the wastewater coming from production process.

Further checks are carried out on fumes released into the atmosphere.

In 2010 Aureli inaugurated a Bio-Mass plant for the production of Green Energy starting from the processing of vegetables waste and from corn grown for crop rotation. The annual energy production is around 1,000 kW.

Beside the production of clean energy, the so-called "digestate" is obtained from the fermentation process, a real natural fertilizer, which AURELI uses to rebalance the levels of micro and macro elements of the soil.

QUALITY CONTROL

The Quality laboratory is made up of seven operating units that deal with chemical, microbiological and physical analyses of the incoming raw material, the fresh and processed product.

RESEARCH AND DEVELOPMENT DEPARTMENT